Heidelberg Materials UK is building the world’s first carbon capture facility to enable fully decarbonised cement production at our Padeswood site in north Wales. Once operational, the facility will produce evoZero carbon-captured near zero cement and act as a global exemplar for sustainable cement production.

Cement is an essential construction material with no viable alternative. It is the ‘glue’ in concrete, the most widely used building material in the world, which is used to build homes, schools and hospitals, as well as in crucial infrastructure such as wind farms, tunnels and roads.

But cement production is carbon intensive, with a large proportion of these emissions arising from the chemical reactions that take place during cement making, so significant reductions in emissions cannot be achieved by using low carbon or renewable energy sources. The only way to produce the cement that the UK needs, without emitting large amounts of carbon, is to capture and store these emissions before they enter the atmosphere.

Carbon capture and storage (CCS) does exactly what it says – capturing carbon dioxide produced during cement manufacture before it enters the atmosphere, transporting it by pipeline, and storing it safely under the seabed. It is a safe and proven technology that has been around for many years.

To find out more about our CCS strategy, our global projects and the technology we are using, visit our CCUS experience website here.

Latest update

We have signed an engineering, procurement and construction management contract (EPCM) with Mitsubishi Heavy Industries and Worley, marking the next milestone in our plans to build the UK’s first carbon capture facility at a cement works at our Padeswood site in north Wales. The facility is set to be operational in 2029, enabling the production of evoZero carbon captured near-zero cement.

HyNet North West

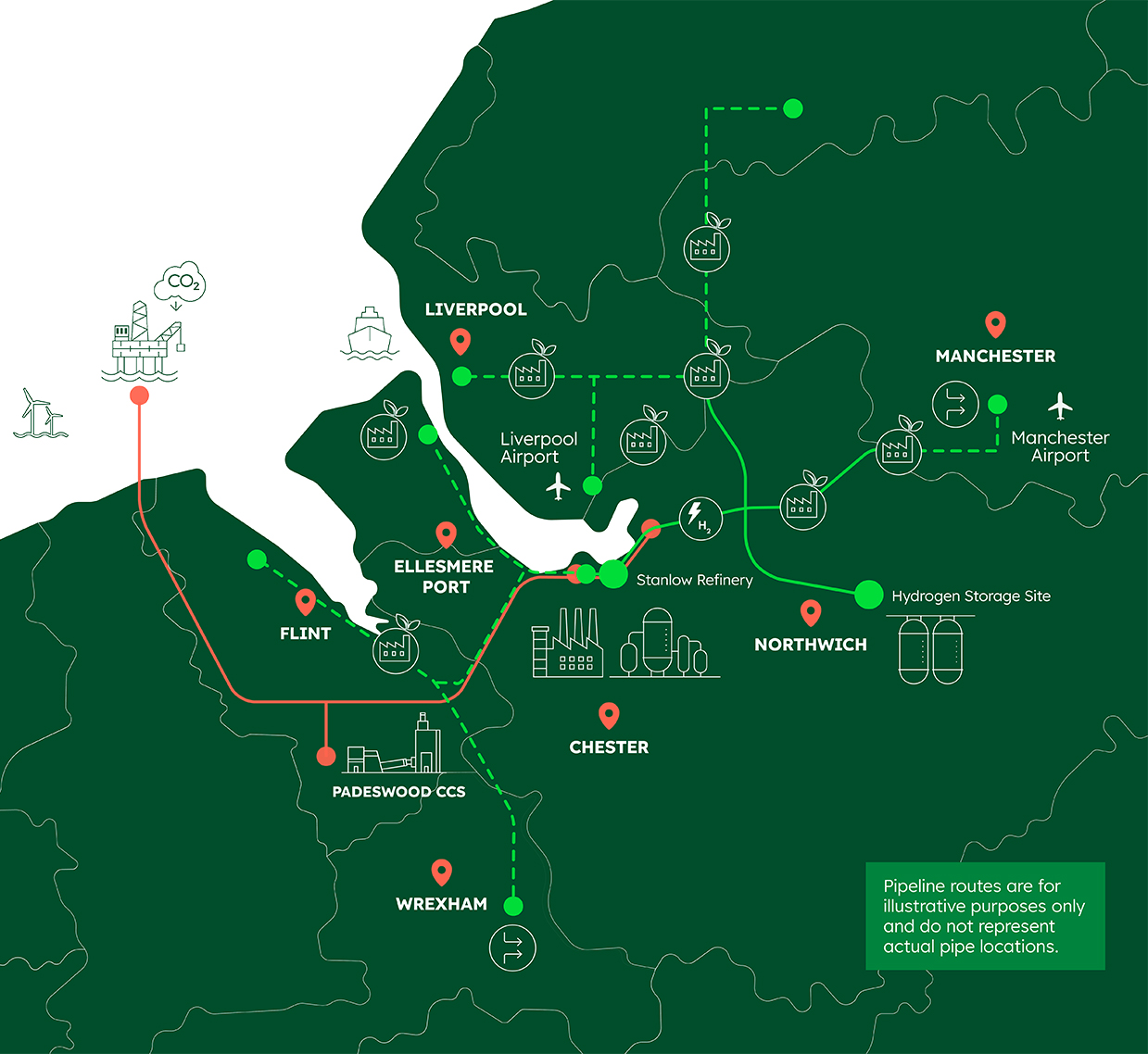

Our Padeswood CCS project is an important part of the wider HyNet North West decarbonisation cluster, which stretches from Flintshire and Wrexham, through Cheshire and Liverpool and into Greater Manchester.

HyNet is a complex project that aims to reduce carbon emissions by 10 million tonnes a year by capturing CO₂ and providing locally-produced low carbon hydrogen to power industry and heat homes. The carbon capture facility at Padeswood will account for around 800,000 tonnes a year of this substantial saving.

The CO₂ captured at Padeswood will be compressed and transported to the wider HyNet transportation and storage (T&S) system via a 10km spur pipeline for safe and secure storage in depleted natural gas reserves under the seabed in Liverpool Bay.

The T&S system is being operated by Eni, which is repurposing offshore platforms and 149km of onshore/offshore pipelines and constructing 35km of new pipelines to connect Padeswood and others in the HyNet cluster.

Project benefits

In addition to its environmental benefits, the project will:

- bring significant investment to Padeswood cement works and the region’s economy;

- help to secure a sustainable future for 2,500 people employed in the UK cement industry, 15,000 indirect jobs, and 2.5 million jobs in the construction industry;

- protect more than 200 direct and indirect local jobs;

- create around 50 new full-time jobs at Padeswood, and up to 500 more during construction of the carbon capture facility.

Padeswood CCS will support the transition of the wider construction industry to a net zero future, ultimately helping the UK meet its decarbonisation targets.